WEIGHBRIDGES

Coastal Scales & Registers has been installing, servicing, repairing and verifying weighbridges for over 30 years. We’ve been through a few brands in that time however have settled on the Ultrahawke 9630s and variants, generally with Flintec load cells and Rinstrum Indicators. In the last few years we have installed a number of new Ultrahawke weighbridges as far afield as Glen Innes, in lengths from 20m to 28m . We have also converted mechanical weighbridges and performed complete retrofits on many older bridges. With each of these jobs, Ultrahawkes’ Engineering Department have made specific design changes to suit the individual site due to space restrictions or ground problems. There is no such thing as a standard weighbridge with Ultrahawke - so don’t accept an ‘off the shelf’ one from anyone else.

ABOVE-GROUND WEIGHBRIDGES

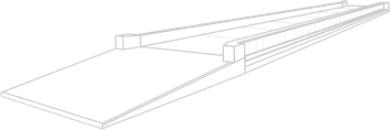

Above-ground weighbridges can be supplied in single deck, twin deck or multi-deck configuration depending on the needs of the application. Above-ground weighbridges are the most commonly supplied type of weighbridge systems due to their cost-effectiveness. This type of weighbridge is also popular as it requires the least amount of site preparation before construction. However, it's important to consider the space available on-site. Above-ground weighbridges claim the most surface area of a site of any type of weighbridge. When planning for an above-ground weighbridge, entry/exit ramps of at least 5m in length and 1m "clear-spaces" along both sides of the weighbridge deck need to be taken into account.GROUND-LEVEL WEIGHBRIDGES

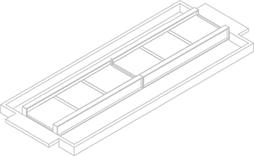

If you need a weigh in motion weighbridge for your site, look no further than Ultrahawke. We manufacture and install WIM systems, semi-pit ground-level weighbridges in both standard and custom configurations, depending on the specific needs of the application. Our ground-level WIM weighbridges can be multi-deck, twin deck or single deck, depending on the length of the vehicles needing to be weighed. One major advantage of a ground-level weighbridge is that no ramps are required, making them a cost-effective and sensible option where a site is limited with space for a weighbridge. Some civil works, including excavation and sump or drainage pipe installation are essential for installation of a ground-level weighbridge. Additional work may be required for reinforcement in the side walls if traffic needs to travel adjacent to the side wall area. Weighbridge walkways generally also need to be installed alongside the deck at either deck level or at beam height level to maximise safety for vehicle drivers and site personnel. The walkway may extend the full length of the deck or just part of it. In either instance, load cells must be able to be easily accessed by weighbridge service personnel.FULL PIT IN-GROUND WEIGHBRIDGES

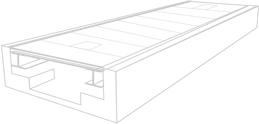

This fully in-ground weighbridge option is ideal for sites with extreme space restrictions and/or shared weighing and traffic areas. This type of weighbridge is also suitable for sites where vehicles are weighed during loading by forklifts. Depending on the needs of your application, a full pit in-ground weighbridge can be supplied by Ultrahawke in a multi-deck, twin deck or single deck configuration. The weighing surface of a fully in-ground weighbridge is completely level with the surrounding ground level, requiring extensive excavation work, effective drainage and slightly more concrete and reinforcing. This means that full pit in-ground weighbridges are the most expensive weighbridge type to construct. Access to the weighbridge's load cells is included via access holes in the deck itself, or to the side of the deck as part of the foundation design. OHS requirements mean that service personnel must be specially equipped, with a minimum of two present on-site, meaning full-pit weighbridges are typically more costly to service than other weighbridge types. If you are not sure which weighbridge type is most suited to your needs and budget, please contact Coastal Scales & Registers and one of our experts will be happy to answer your questions.

LOOKING FOR CASH REGISTERS AND POINT OF SALE? CLICK “HERE”

WEIGHING UP YOUR OPTIONS SINCE 1984!

WEIGHING UP YOUR OPTIONS SINCE 1984

© Coastal Scales & Registers 2020

ABOVE-GROUND WEIGHBRIDGES

Above-ground weighbridges can be supplied in single deck, twin deck or multi-deck configuration depending on the needs of the application. Above-ground weighbridges are the most commonly supplied type of weighbridge systems due to their cost-effectiveness. This type of weighbridge is also popular as it requires the least amount of site preparation before construction. However, it's important to consider the space available on- site. Above-ground weighbridges claim the most surface area of a site of any type of weighbridge. When planning for an above-ground weighbridge, entry/exit ramps of at least 5m in length and 1m "clear-spaces" along both sides of the weighbridge deck need to be taken into account.GROUND-LEVEL WEIGHBRIDGES

If you need a weigh in motion weighbridge for your site, look no further than Ultrahawke. We manufacture and install WIM systems, semi-pit ground-level weighbridges in both standard and custom configurations, depending on the specific needs of the application. Our ground-level WIM weighbridges can be multi-deck, twin deck or single deck, depending on the length of the vehicles needing to be weighed. One major advantage of a ground-level weighbridge is that no ramps are required, making them a cost-effective and sensible option where a site is limited with space for a weighbridge. Some civil works, including excavation and sump or drainage pipe installation are essential for installation of a ground- level weighbridge. Additional work may be required for reinforcement in the side walls if traffic needs to travel adjacent to the side wall area. Weighbridge walkways generally also need to be installed alongside the deck at either deck level or at beam height level to maximise safety for vehicle drivers and site personnel. The walkway may extend the full length of the deck or just part of it. In either instance, load cells must be able to be easily accessed by weighbridge service personnel.FULL PIT IN-GROUND WEIGHBRIDGES

This fully in-ground weighbridge option is ideal for sites with extreme space restrictions and/or shared weighing and traffic areas. This type of weighbridge is also suitable for sites where vehicles are weighed during loading by forklifts. Depending on the needs of your application, a full pit in- ground weighbridge can be supplied by Ultrahawke in a multi-deck, twin deck or single deck configuration. The weighing surface of a fully in-ground weighbridge is completely level with the surrounding ground level, requiring extensive excavation work, effective drainage and slightly more concrete and reinforcing. This means that full pit in- ground weighbridges are the most expensive weighbridge type to construct. Access to the weighbridge's load cells is included via access holes in the deck itself, or to the side of the deck as part of the foundation design. OHS requirements mean that service personnel must be specially equipped, with a minimum of two present on-site, meaning full-pit weighbridges are typically more costly to service than other weighbridge types. If you are not sure which weighbridge type is most suited to your needs and budget, please contact Coastal Scales & Registers and one of our experts will be happy to answer your questions.